Globalization and pandemic disruptions have caused the rise of the e-commerce sector. As a result, the need to provide customers with products around the globe has also increased. It has resulted in logistics companies increasing their workload. In business, fast and timely delivery is a managerial priority so that clients get their products on time. To cope with the increasing load, complex solutions such as automation and digitalization are required to quicken processing and increase the effectiveness of logistics operations.

According to United Nations Conference on Trade and Development (UNCTAD), after the pandemic, the sales share of the e-commerce sector worldwide rose from 16% to 19%. The sector is largely controlled by advanced logistics software, which is capable of handling requests from customers, processing orders, locating required products, processing the sale, and moving the product to the shipment area where it will be transported within the specified period. The 3% growth is indicative of how logistics software solutions benefit logistics companies.

Large retailers such as Shopify and Walmart, who had implemented the logistics management system into their operations, saw their profits increase by 95% and 72%, respectively. Therefore, this article will concentrate on the operation and benefits of some of the best logistics management software you should consider implementing in 2024.

Table of Contents

Demand for Logistics Management Software

The ever-increasing demand for products has resulted in high demand for supply chain management software solutions (SCMS). In addition, the need to deliver products to the customer wherever they may be has seen the rise of SCMS being the most sought-after software in logistics and supply chain industries.

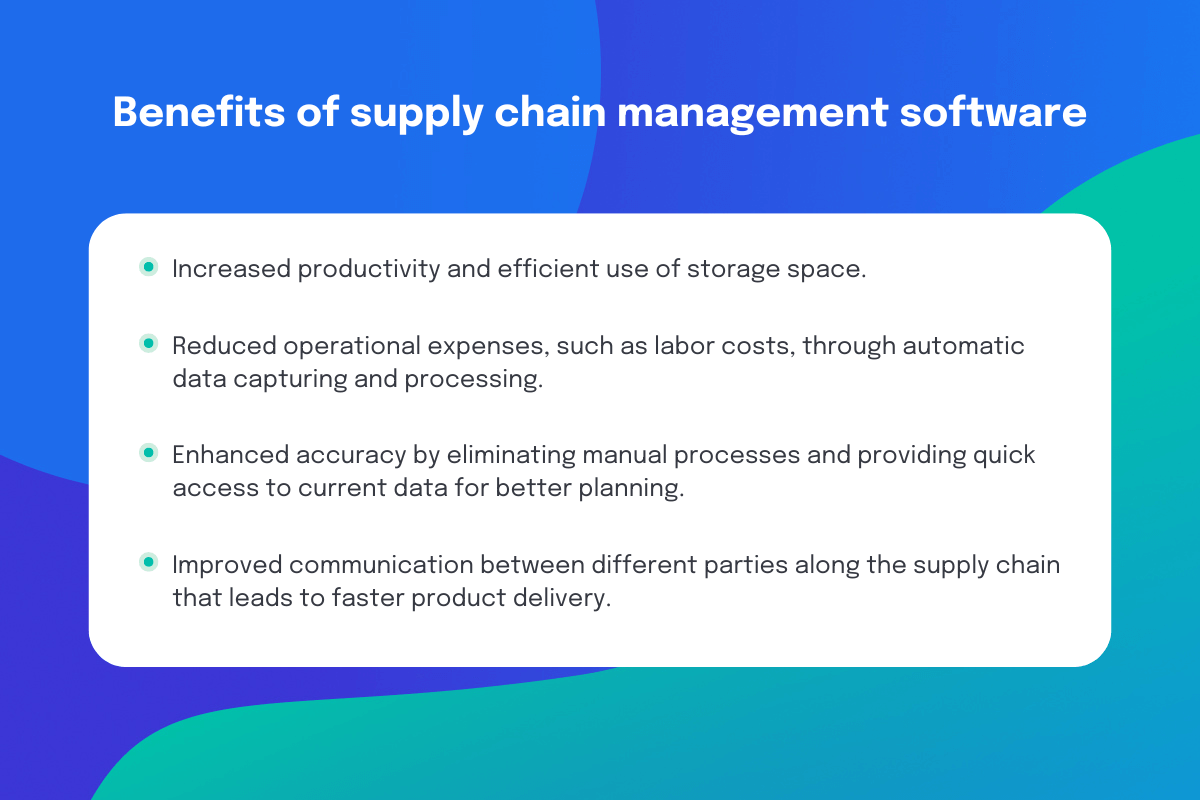

This year, market sales for SCM technology are more than $28.9 billion—and growing. It proves the vast benefits of SCM tech that organizations have become aware of. By the end of 2022, it was predicted that around 620,000 units of warehouse automation technologies were going to be purchased. This information clearly shows that the future of warehouse logistics is in SCMS. Major benefits of SCMS include:

- Increasing productivity and efficient use of storage space.

- Decreasing operational expenses such as labor costs through automatic data capturing and processing.

- Improving accuracy by eliminating manual processes and quick access to current data for better planning.

Logistics Software Solutions for Optimized Supply Chain Management

Fortunately, the available logistics 3PL warehouse management and supply chain technology provide logistic companies with tools to develop better risk management strategies. Partnering with the best 3PL companies ensures access to these advanced technologies and expertise, facilitating efficient warehouse management and supply chain optimization. Below are some of the best chain supply management software to be aware of for 2024. Many large companies like Amazon have already implemented these solutions. The operation and benefits of each software are outlined below.

Robotic Process Automation (RPA) & Hyper-Automation

Many companies are implementing hyper-automation into their operations. A highly business-driven approach is the use of logistics software to replace humans in performing tasks. As a result, a business can reduce costs and generate more revenue to experience a quicker ROI. The software controls every functionality of the robots in operation.

Robotic process automation (RPA) necessitates implementing digital transformation within the organization. The automation process provides the business with numerous benefits, including:

- Eliminating human error.

- Reducing the number of employees, minimizing staff administration costs.

- Multitasking robots that are fast and precise in performing tasks involved in inventory management.

- Quicker collection and processing of data.

Historically, people have been responsible for grading and sorting products in warehouses. The RPA enables the efficient execution of these processes automatically using the appropriate software solutions under the robot’s control. The robots can move items to any location in the storage facility quicker and more accurately. Additionally, they keep a record of every process they perform for easy traceability. The automatic moving, grading, and sorting remove the human element from the process.

Another major advantage of RPA is that the robots can perform completely different tasks. How? You just change the software—and you are good to go, unlike people who would require days of training to become efficient. As a result, automation saves companies time, money, and resources.

The organization witnesses increased profits as a result of reducing the number of employee salaries. The automation process provides a near error-free working process, which reduces the number of inconveniences, such as misplacing an item. By implementing an RPA, an organization won’t require record keepers as the robots can perform the task perfectly.

Furthermore, RPA has resulted in the creation of intelligent process automation (IPA). The IPA aims to remove the need for any paperwork between the supply warehouses and the customer. The IPA facilitates the effective blending of digital efforts and customer experience.

The IPA is capable of helping customers make the right choice according to their preferences through intelligent algorithms. For the business side, the IPA is useful in predicting future changes in demand. It helps the business to prepare accordingly, whether by increasing supplies or storage allocation for different products.

Supply Chain Visibility

Supply chain visibility (SVC) is a warehouse management system that enables you to track and monitor product movement. There are numerous benefits to applying this software.

First of all, companies benefit from increased inventory control measures and safety. If outsourcing manufacturing, investing in contract manufacturing software too will also be a huge help with tracking and controlling stock. The supply chain involves an interlinked network of various companies. Multiple stakeholders’ opinions usually result in inefficient and costly compromises. Even more dangerously, the risk of fraud incidents increases.

Second of all, you can use QR codes for warehouse management to save a lot of paperwork. You can implement a QR code system by using a custom QR code generator for business.

The supply chain visibility offered by different technologies, such as big data, automation software, and AI, ensures the entire supply channel is transparent. The position and movement of each item will be visible to all. If a weakness is identified, security measures are then implemented to ensure the safety of the supply chain.

Other benefits include:

- Increasing logistic management solutions throughout the supply chain.

- For international suppliers, visibility systems are part of the regulations. Therefore, it becomes easier to monitor movement and comply with new rules and regulations.

- Enhanced visibility enables quick problem identification. It allows prompt implementation of corrective measures to reduce expenses. Besides, it optimizes the efficiency of the delivery system.

- Providing quality service which results in customer satisfaction through quick procurement of resources.

The important thing is to choose the right software for business needs. It’s crucial to follow the steps below:

- Understand your organization’s current operations.

- Set your future objectives, especially when the company expands.

- With this information, you can find the best solution to cater to your current needs with the capabilities to scale.

Some of the best solutions include E2open, Oracle SCM, and Logility. The software comes either as a software package or a service. If you prefer the package option, your in-house staff should have the proper training to operate and troubleshoot issues. The service option is most preferred and efficient as all the hard work is done by the service providers, leaving you with improved operations and more time to deal with other urgent business issues.

API-Powered Networks

Application programming interface (API) facilitates the integration of two isolated software systems to cross-communicate and share information. The integration improves the transparency and performance of the operations.

However, before a company starts software development for API integration, it first needs to develop the integration plan. This plan must allow for gradual implementation and monitoring before moving to the next transitional step. It is done to identify errors and perform corrective measures on a manageable portion.

There is also a common mistake that most warehousing and logistics companies make. They typically opt for full integration of API using complex software, which has many capabilities. However, the tricky part is that their staff will probably be incapable of operating the software. This results in extra expenses for hiring experts to be in charge and perform the required maintenance tasks.

Therefore, to avoid any unnecessary complications, logistics companies should follow a gradual implementation plan that ensures an effortless transition with minimal errors.

Big Data & IoT in Inventory Management

In logistics, big data is essential to make decisions and create procedures that improve the overall performance of the entire organization. For example, in transportation, big data is used for the performance management of shippers to ensure that they are always operating optimally. Some of the parameters that big data helps to resolve include:

- The safe and convenient speed of transportation.

- Knowing average fuel consumption to ensure that trucks have enough fuel.

- The best route is the one that provides economical delivery in the shortest possible time. You can track this with a reliable vehicle tracking system.

- Information from big data enables operators to predict and plan with confidence the functionality of every supply chain operation.

- It provides information to the warehouse management system (WMS) to make better use of the storage space.

The next step is to find IT scientists and data analysts to create the software which will collect and analyze your company’s data. This method is often costly, especially if you hire experts, and usually takes time to implement. A better alternative is to hire an agency offering the software as a service (SaaS). This way, all the required complicated integrations are done for you. It’s always best to choose software with a simpler interface and service providers who will maintain the system to prevent any failures.

Custom Supply Chain Management Software

Supply chain management software (SCMS) makes use of other available technologies, such as big data and AI, to ensure that all product features have been analyzed and appropriate action measures have been suggested for implementation. The logistics software includes machine-learning capabilities, which, over time, start to make predictive suggestions to improve the organization’s operations. Some of the parameters analyzed by the software are:

- Pricing. The overall price of the product must be optimal, meaning that it must ensure that the product is profitable and, at the same time, competitive in the market.

- Tradability of the product. The big data from previous deals will assist in analyzing your service delivery. For example, some products are only profitable when supplied locally. As such, quantitative and qualitative analysis of an SCMS will help you come to accurate conclusions.

- Storage. Supply chain management software enables logistic companies to come up with viable storage solutions for the product’s lifecycle. Proper storage is essential for preserving a product’s quality.

- Factory adjustments. Different products require different manufacturing, storage, and transportation procedures. The SCMS makes it easy to identify such products so that preparations can be made beforehand. Also, the identification of seasonal products becomes easier. The organization can then keep enough supplies for the decreased demand while creating new space for other products.

The SCMS is useful in organizations with repetitive, complex, and time-consuming processes. The logistics software easily solves all of these through the use of various technologies. Repetitive tasks performed using SCMS are completed much quicker and with increased precision that far exceeds human capabilities. Time-consuming tasks are usually the ones that require the assessment of different factors. The SCMS shortens the duration of the processes as it can take into account various parameters simultaneously and perform complex calculations within a fraction of a second. This way, you will get all the information you need available in an instant.

To predict the future accurately, humans would need supernatural powers. However, effectively using big data and AI tools, you can provide forecasting services.

If you need quality software engineers to create custom software for you, YouTeam can provide the needed specialists.

Browse 500+ Dev Teams Available for Hire

Transportation Management Software

Transport management software (TMS) enables an organization to plan, prepare, and efficiently execute the movement of goods from one point to another. The transport management system is part of the supply chain management system. It tracks the movement of inbound and outbound goods. The TMS provides transparency with the movement of products and ensures that compliance and other documents streamline with current international standards. It ensures that unnecessary delays are avoided, and products arrive on time. It becomes easier for organizations to plan fleet management and transportation operations through various channels, whether by air, land, or sea, to reach customers as fast as possible.

Benefits of TMS include:

- Automating many slow manual processes results in effective product management and faster order fulfillment.

- Providing better customer service through real-time notifications for products in transit. Coupled with fewer arrival delays, it leads to increased customer satisfaction.

- Scaling enables the service providers to make adjustments with ease and meet customer demands quicker.

- Simplifying supply chain processes through automation resulting in accurate documentation and easily manageable business operations. It enables the business to offer more competitive prices.

Transport management software affects every business logistical operation process of an organization. It influences planning, transportation, and other departments and provides visibility, which leads to better planning and transportation. It ensures that customers get their products on time and the clients are satisfied. As a result, the organization experiences higher customer retention and attracts more consumers. Increasing the number of customers leads to higher profitability. As customer expectations continue to rise, using TMS allows for a smooth and efficient transportation system. In this competitive era, time is money.

Asset Monitoring and Tracking

Logistics companies worldwide receive and transport millions of different products every year. Furthermore, their numbers significantly rose during the pandemic with worldwide curfews and travel restrictions. As such, the integrity of the product should be intact from supplier to consumer. Transportation is the most vulnerable stage in the supply chain process. Goods are susceptible to damage, theft, and spoilage, which greatly affect the supplier’s reputation. It results in a loss of customers and revenue.

An asset monitoring and tracking system (AMTS) provides the status condition of the products’ security as they move along the supply chain. The system monitors the shipment location and other ambient conditions, such as pressure, temperature, and humidity. Other systems, such as Capgemini, offer cloud-based solutions, which provide near real-time monitoring for easy analysis and quick intervention in case of an anomaly. This SaaS product enables small third-party logistics companies to improve business workflows.

How Do These Solutions Transform the Logistics and Supply Chain Management?

- The company is more profitable from reduced costs due to better storage optimization, route planning, and improved transportation procedures.

- The supply chain solutions provide improved communication between different parties along the supply chain. Better collaboration has led to speedier product delivery.

- The organization can make quick adjustments to meet the dynamic shifts in supply and demand.

- The documentation becomes easier, and processing is almost automatic, resulting in fewer delays.

- Automating manual processes decreases the number of delays and reduces associated labor expenses, resulting in reduced service costs.

- The software enables better warehouse management of resources, such as space minimizing wastage, making the business even more viable.

Wrap Up

The growth of the e-commerce sector has resulted in the need for sophisticated methods of transport management. It ensures that the goods arrive at the appointed destination at the set time. Various technologies are available to improve and optimize the planning, storing of transportation, and many other processes involved in SMC operations.

This article explained how to improve most processes in a logistics company. If you automate one particular field, it will improve efficiency and cut some business costs. For this reason, leading companies have long been on the way to automation and digitalization. If you want to be among the top e-commerce suppliers, the above solutions help set up processes to take your business to the next level.